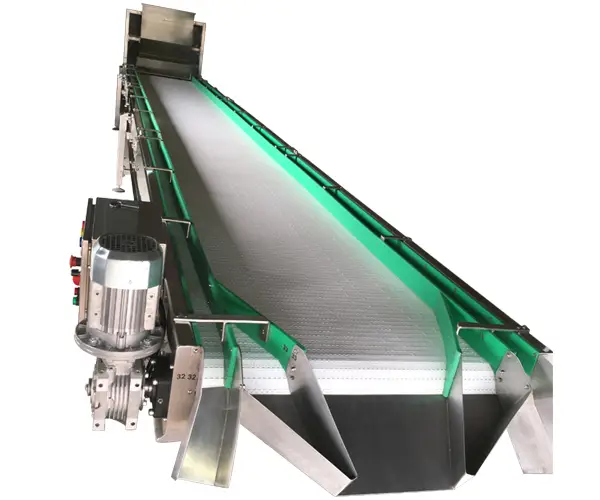

When handling goods that contain oils, fats, or greases—things that would normally cause conventional rubber belts to deteriorate—an oil-resistant conveyor belt made especially for the job. With a superb resistance to the harmful effects of mineral oils, vegetable oils, and animal fats, this belt is made with unique synthetic rubber compounds. It is frequently utilized in sectors where interaction with oily materials is frequent, including production, both of petrochemical, food processing, and recycling. Oil-resistant belts require less maintenance and have a longer service life because they retain their strength, flexibility, and performance even in challenging conditions. Reliable and safe material handling is ensured by its sturdy structure, which guarantees continuous performance. This makes it perfect for transporting processed foods, industrial trash, and oily metal components without slippage or belt swelling.

Selecting an oil-resistant conveyor belt guarantees enduring functionality and dependability while managing goods that are subjected to oils, greases, or chemical residues. Regular replacements and downtime can result from standard conveyor belts being exposed to such contaminants because they can deteriorate, bulge, or crack. An oil-resistant belt is made of premium synthetic rubber that is specifically engineered to withstand oil absorption, preserve structural integrity, and avoid slippage while in use. For challenging settings in sectors like food processing, recycling, petrochemicals, and the automotive industry, this makes it perfect. In addition to lowering maintenance expenses, it guarantees steady material flow and enhances